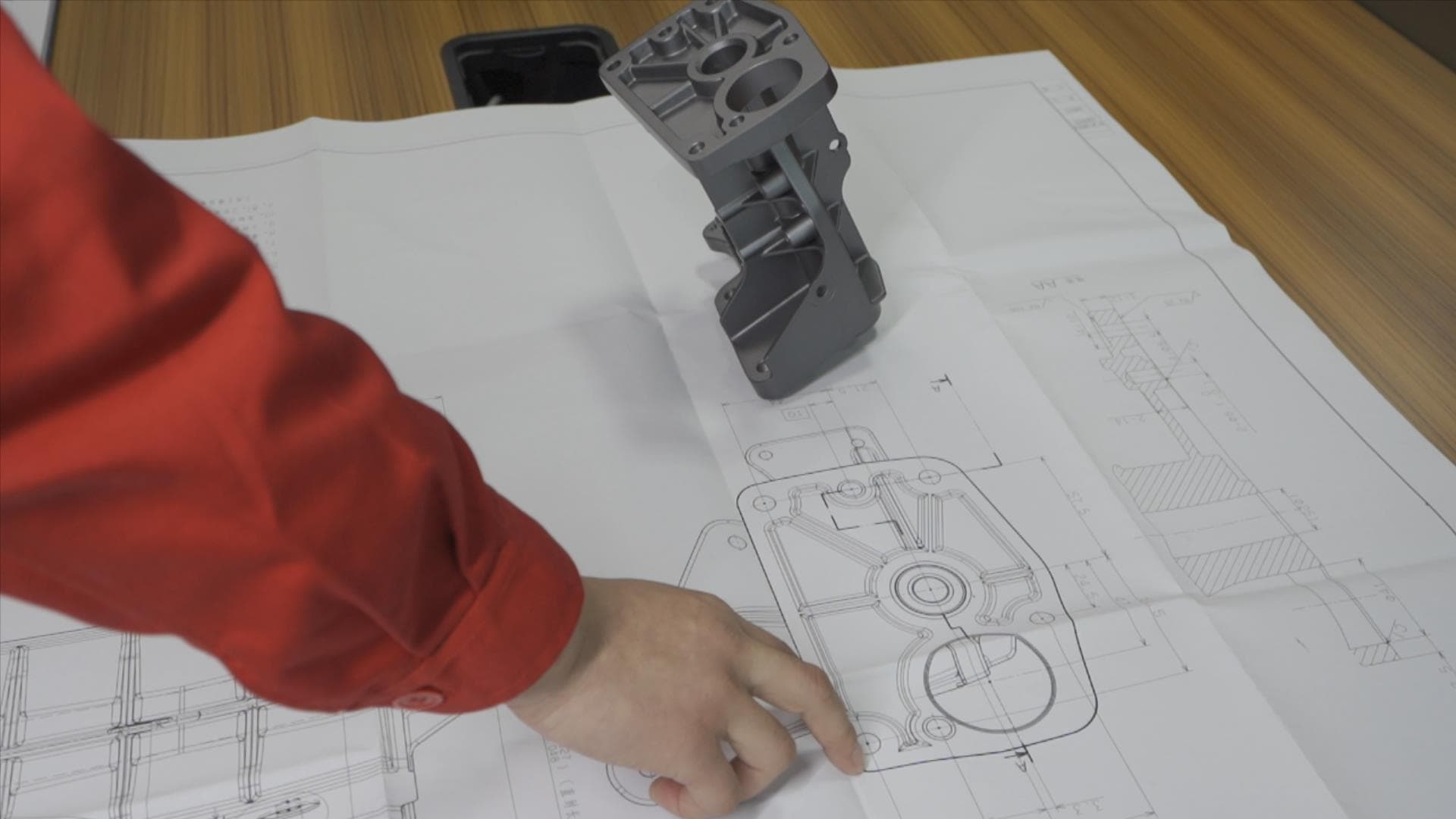

One-stop customized service process: receiving customer drawings, 3D data, samples → process selection (die casting, gravity casting, forging, etc.) → technical disclosure & data modification → confirming mold opening data with the customer → mold design/review/production → tooling design/review/production/verification → preparation of process data, control plan documents → spare parts procurement → mold production completed → die casting trial mold (recording process parameters, compiling and modifying operation standards) → sample verification (full-size verification and necessary performance tests) → CNC processing → surface treatment → cleaning → painting → factory inspection

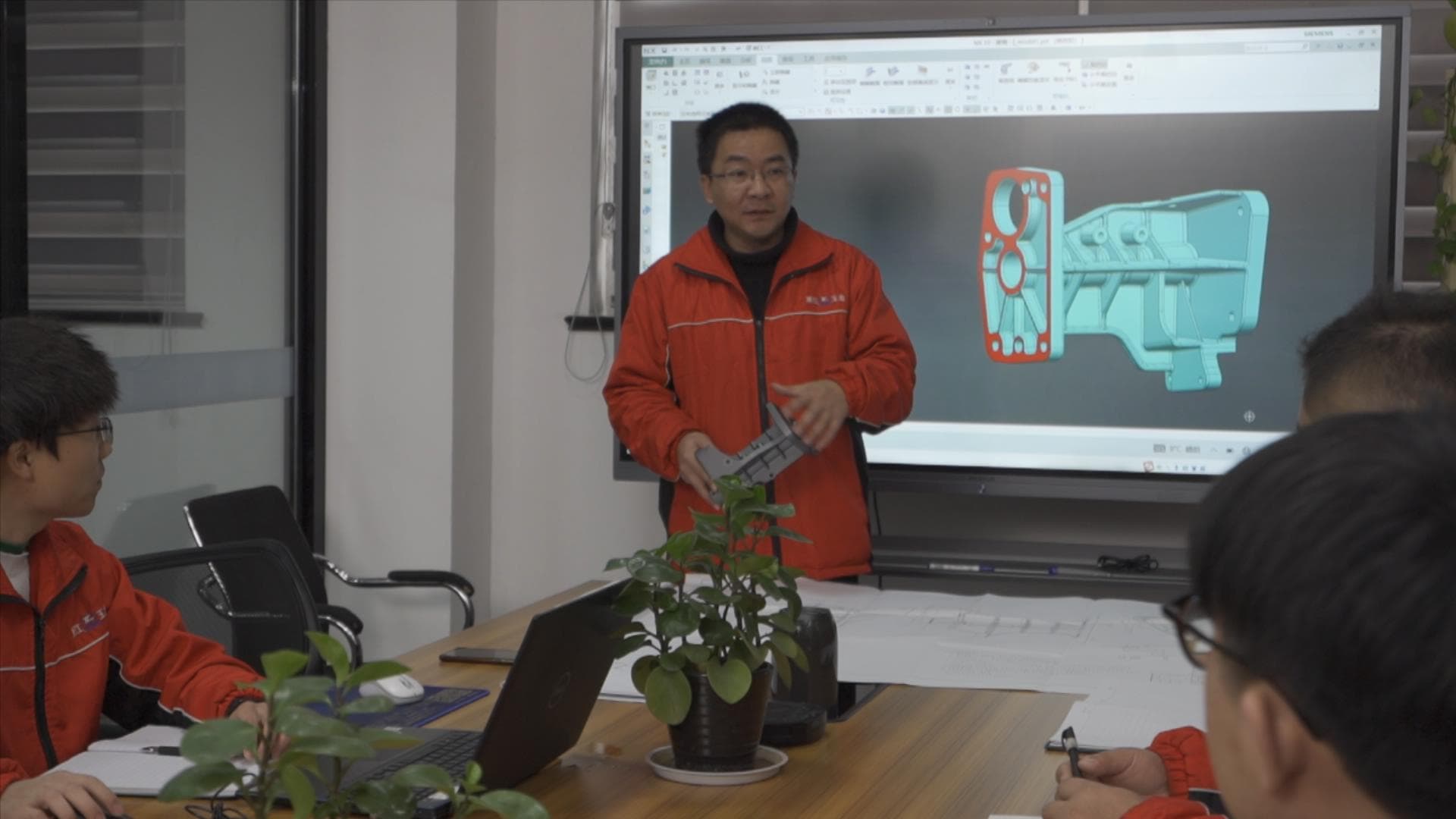

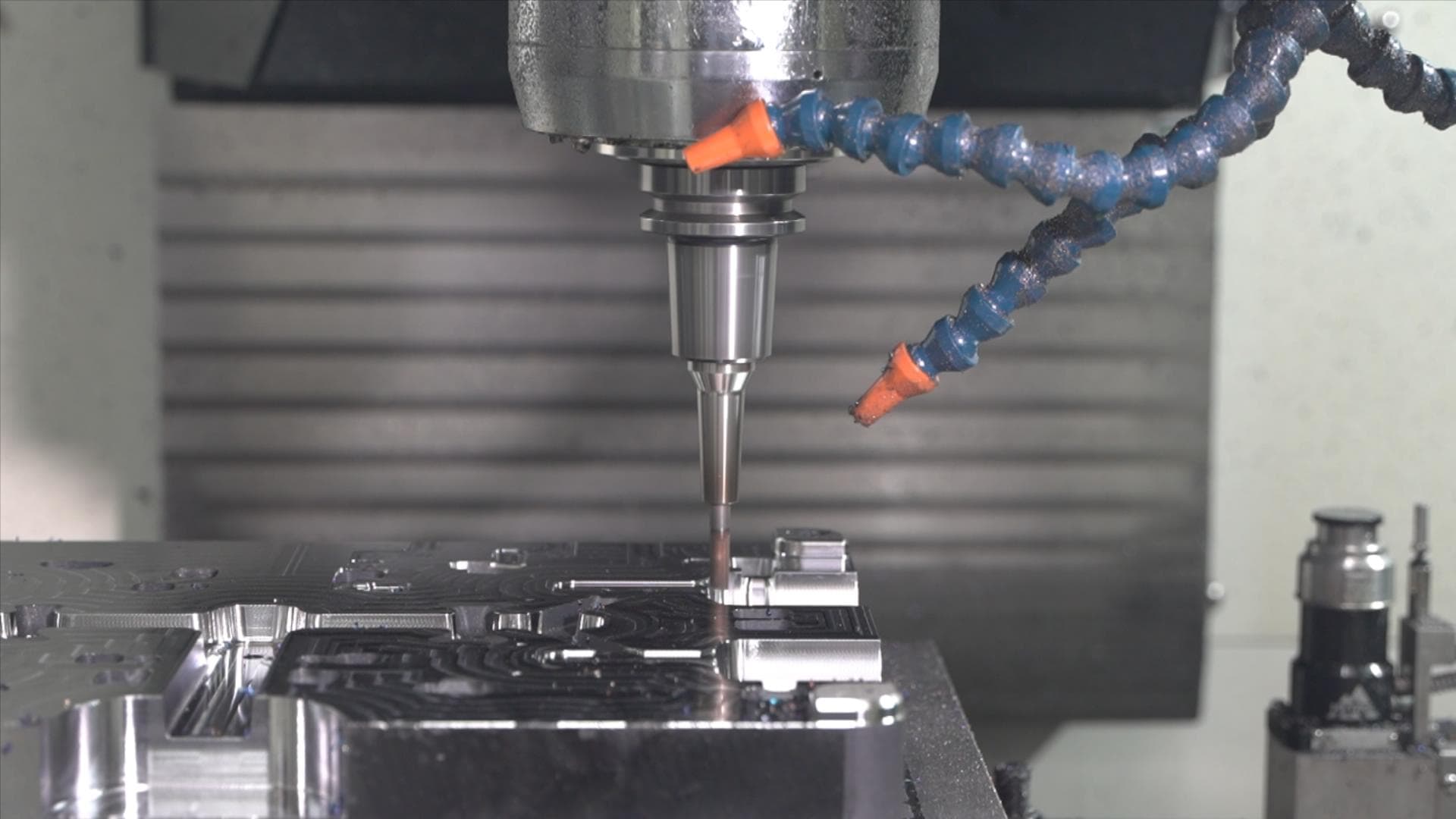

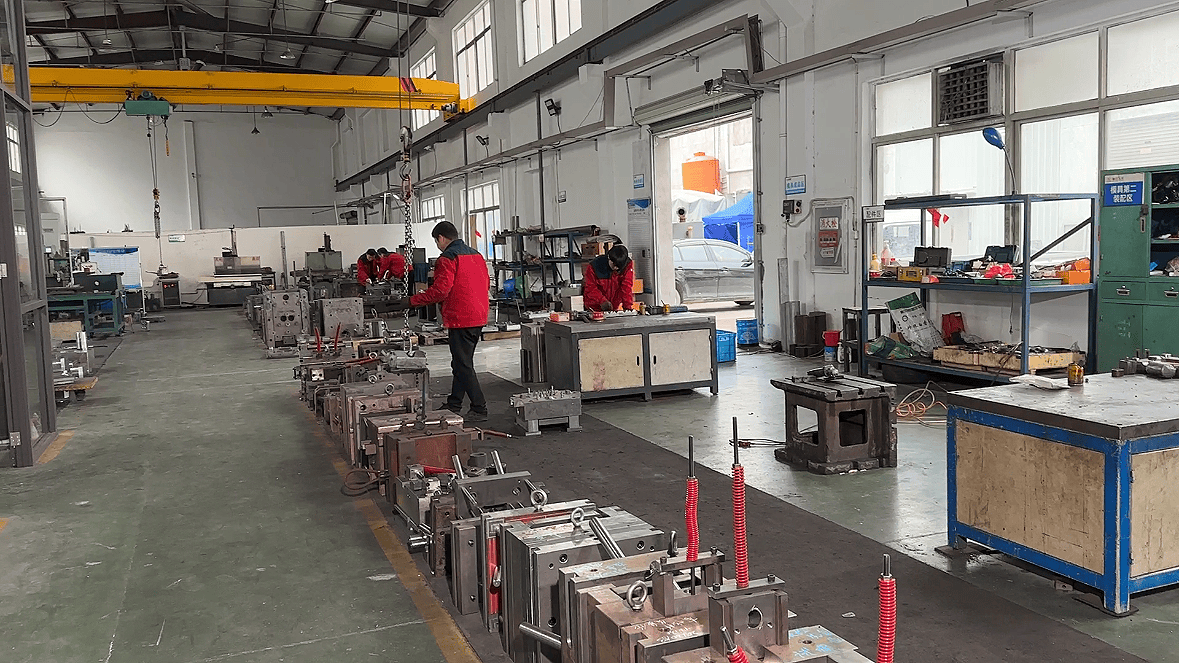

Mold workshop

Mold workshop

equipped with equipment: high-speed milling machine, machining center, precision carving machine, large grinding machine, precision grinding machine, wire cutting machine, EDM machine, mold clamping machine, etc.

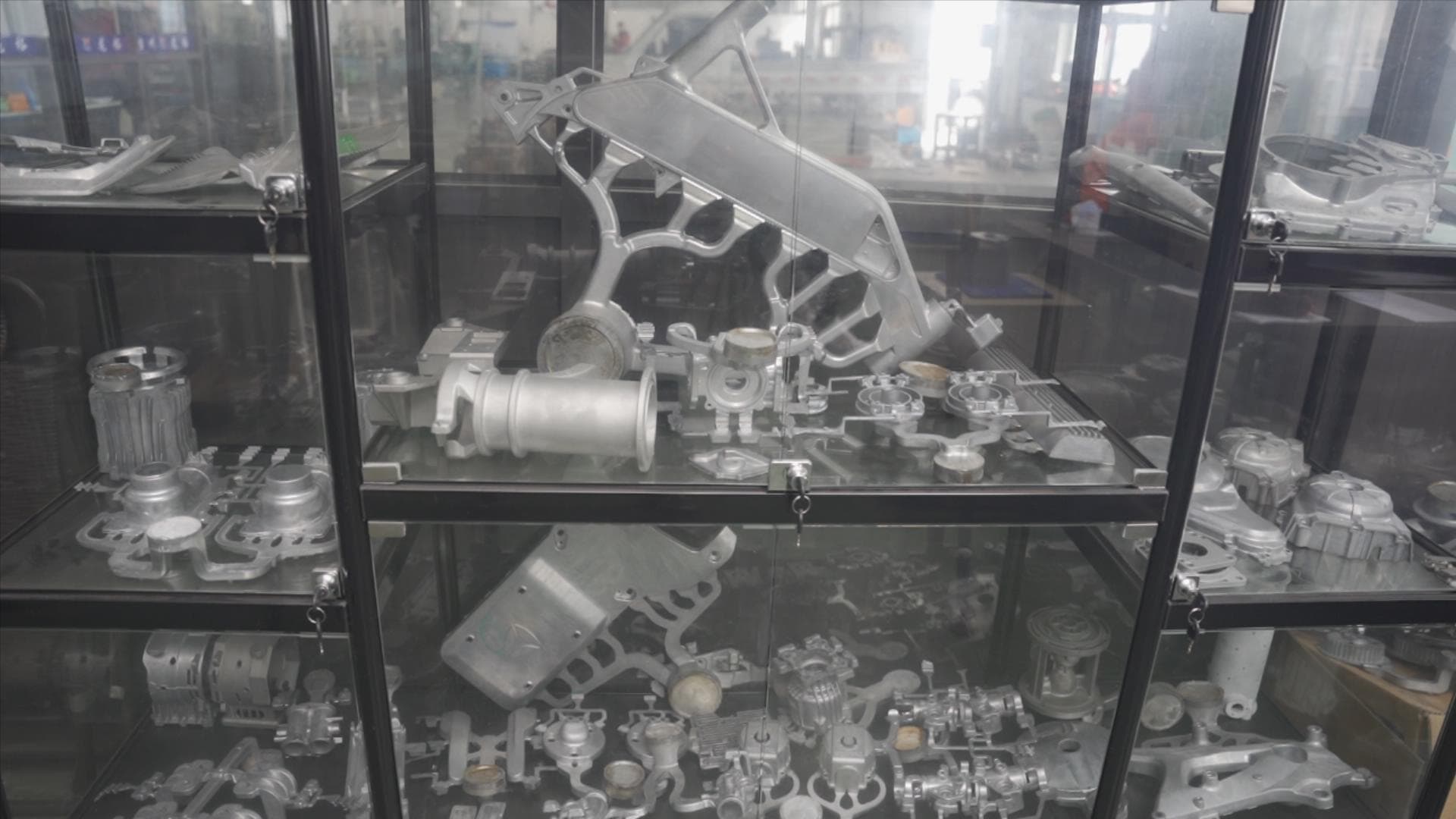

Die-casting molds directly affect the shape, size, precision, surface quality, etc. of aluminum alloy die castings. Whether the quality of aluminum alloy die-castings is guaranteed depends largely on the rationality, advancement and production quality of the die-casting molds. Yulong has a professional team of engineers and designers who can help you develop die-casting parts from scratch. Our die-casting mold design engineer team specializes in using CAD, CAE, CAM for drawing, and analysis software such as SOLIDWORKS, PRO ENGINEER, UNIGRAPHICS and MOLD FLOW.

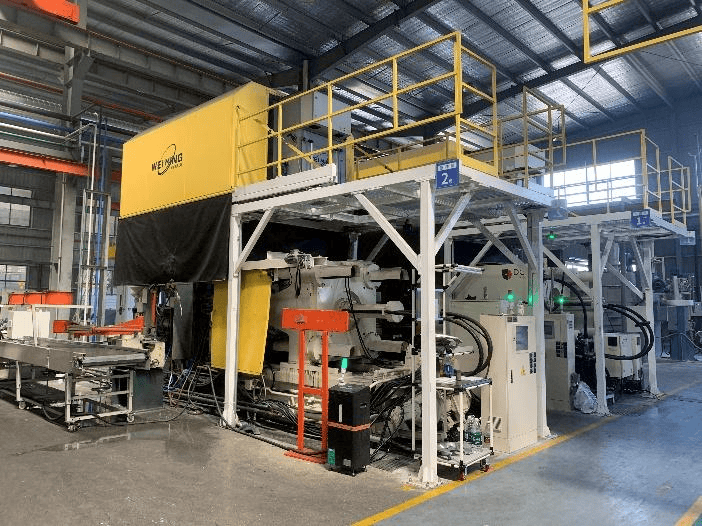

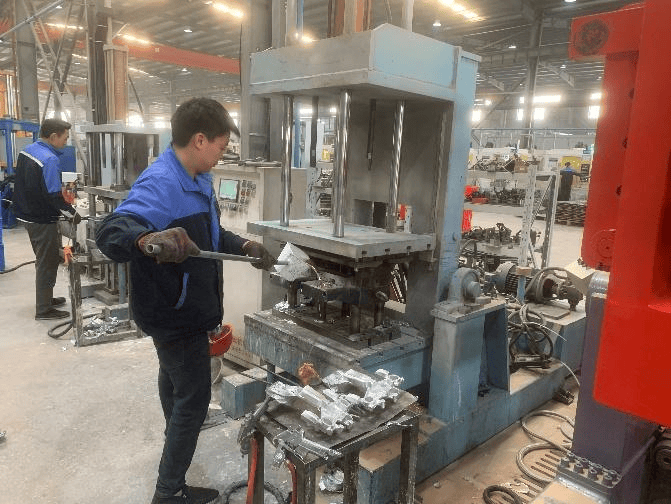

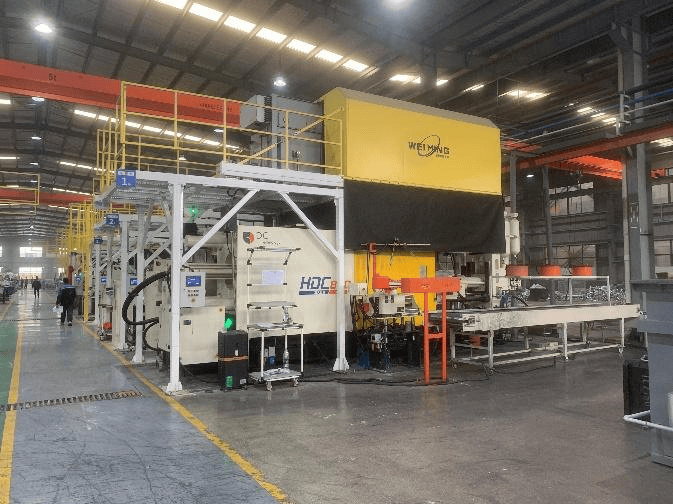

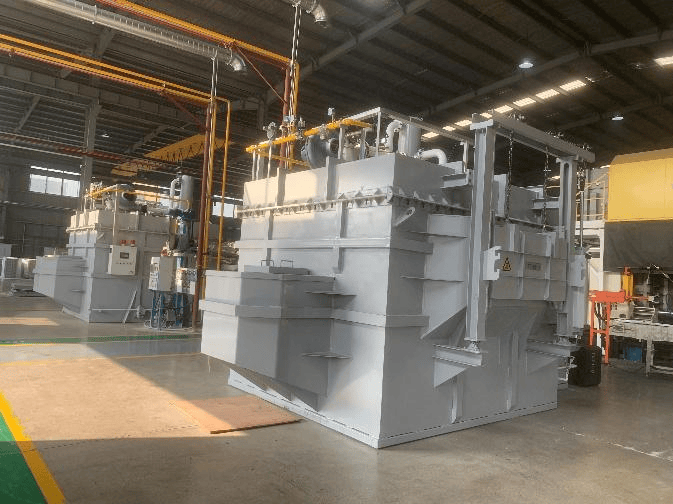

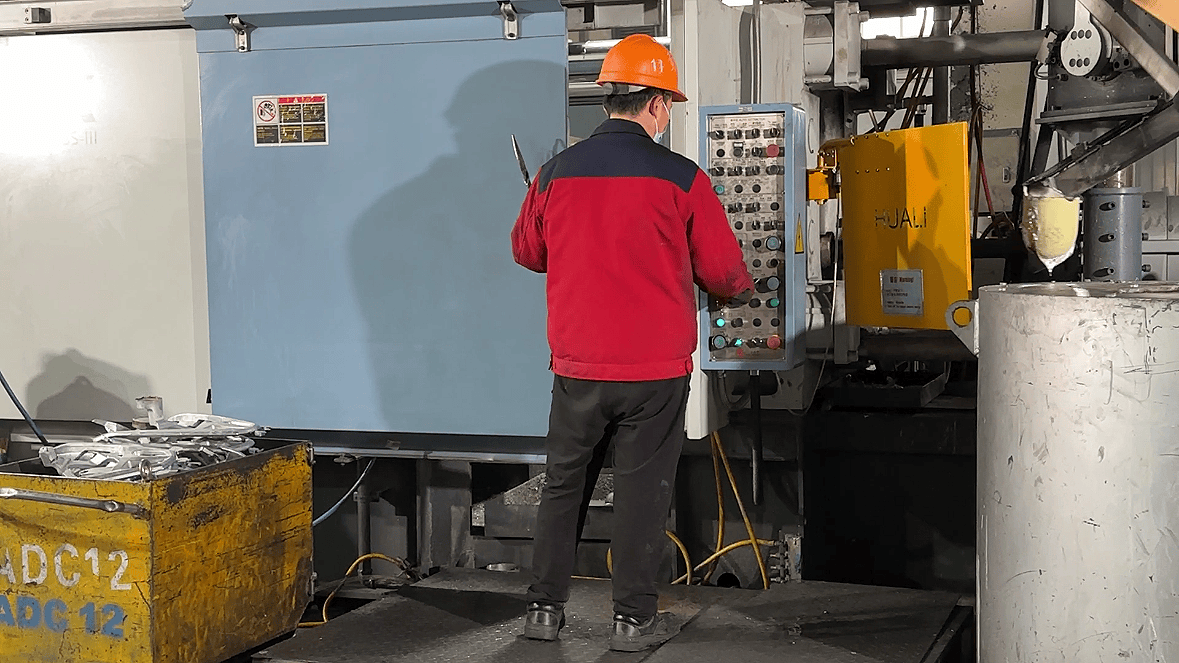

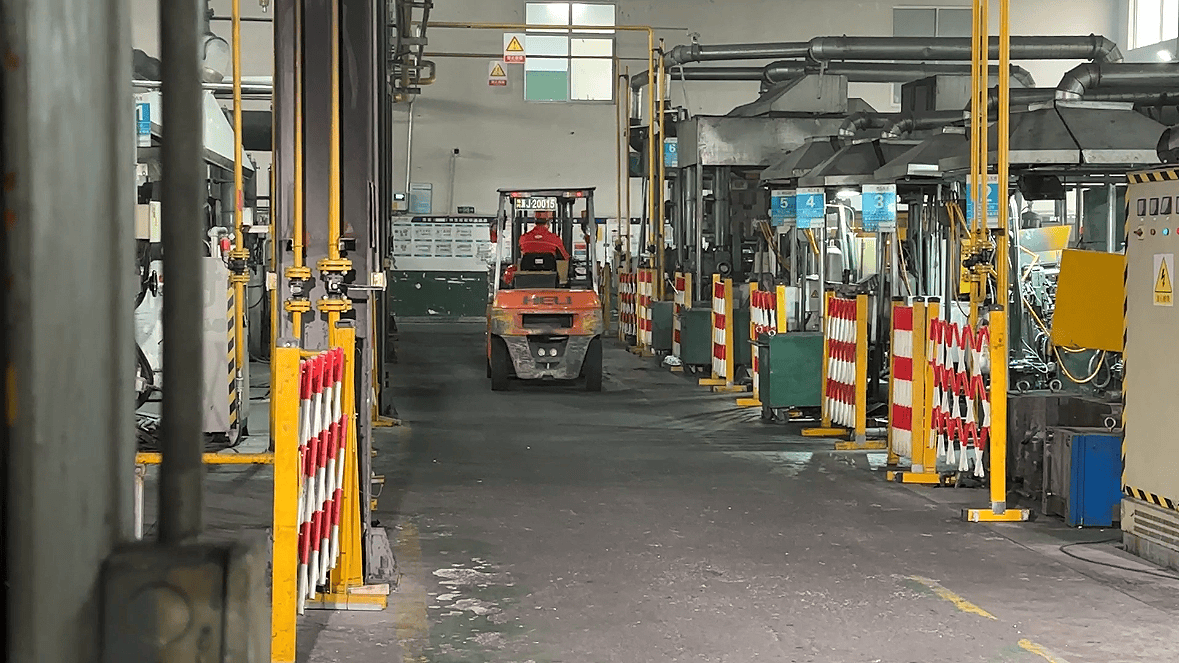

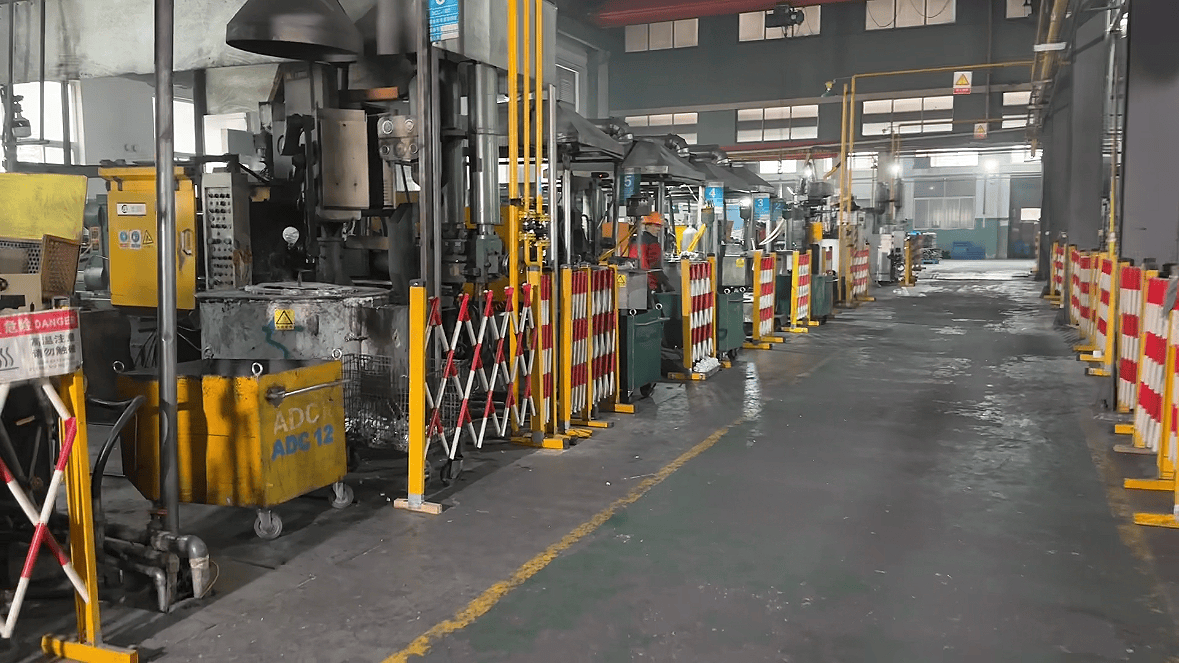

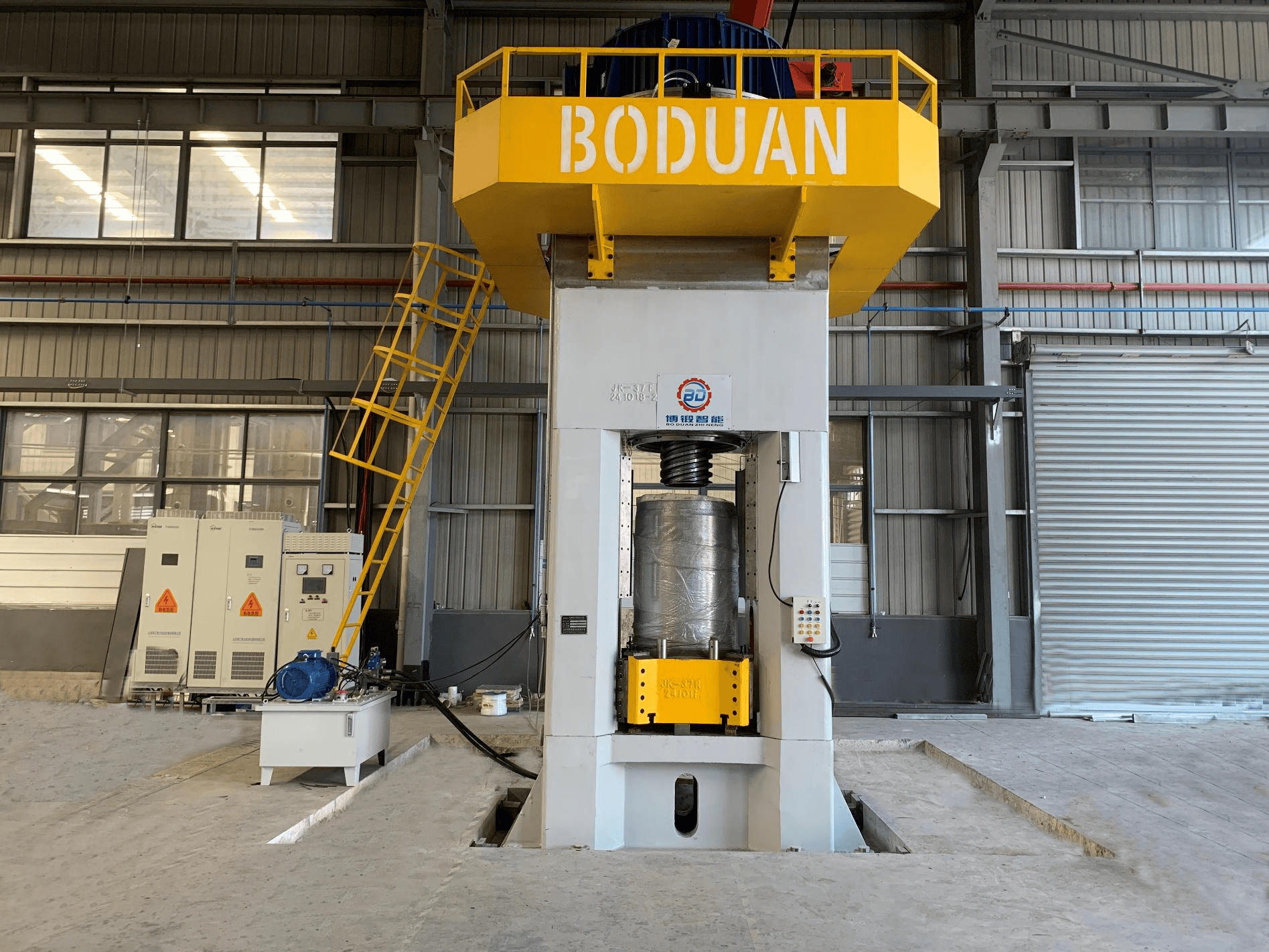

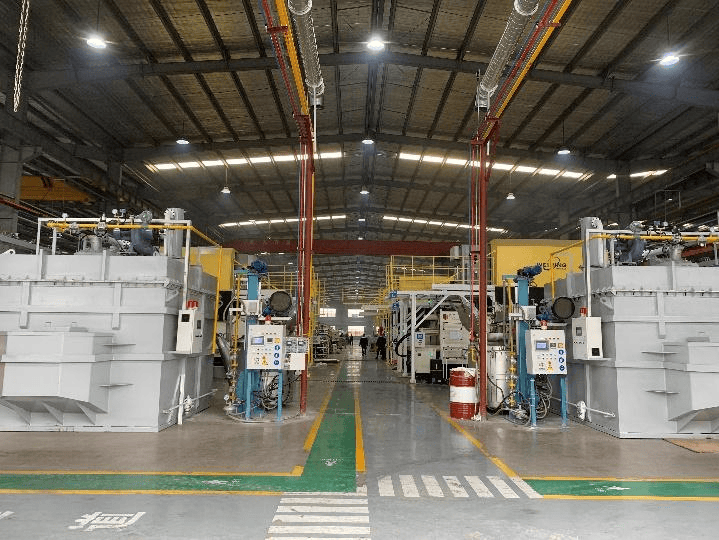

Die-casting workshop

Die-casting workshop

equipped with equipment: hot chamber machine from 30T to 80T, producing zinc alloy products; cold chamber machine from 160T to 800T, meeting the production of various small and medium-sized aluminum alloy parts and components in the automotive and motor industry. We are also equipped with experienced gravity casting masters and automated gravity casting equipment. Structures that cannot be achieved by die casting can be achieved by gravity casting.

Die-casting materials: aluminum alloy: ADC12, ADC6; zinc alloy: 4-0, 4-1

1) Advantages of Yulong die-casting service: It can manufacture casting parts with complex shapes, clear contours, thin walls and deep cavities. Because the fused metal maintains high fluidity under high pressure and high speed, it can obtain metal parts that are difficult to process by other process methods.

2) The dimensional accuracy of die-casting parts is high. It can reach IT11-13 level.

3) High material utilization rate, only a small amount of mechanical processing is required to assemble and use, and some die-casting parts can be directly assembled and used.

4) High production efficiency and can be mass-produced.

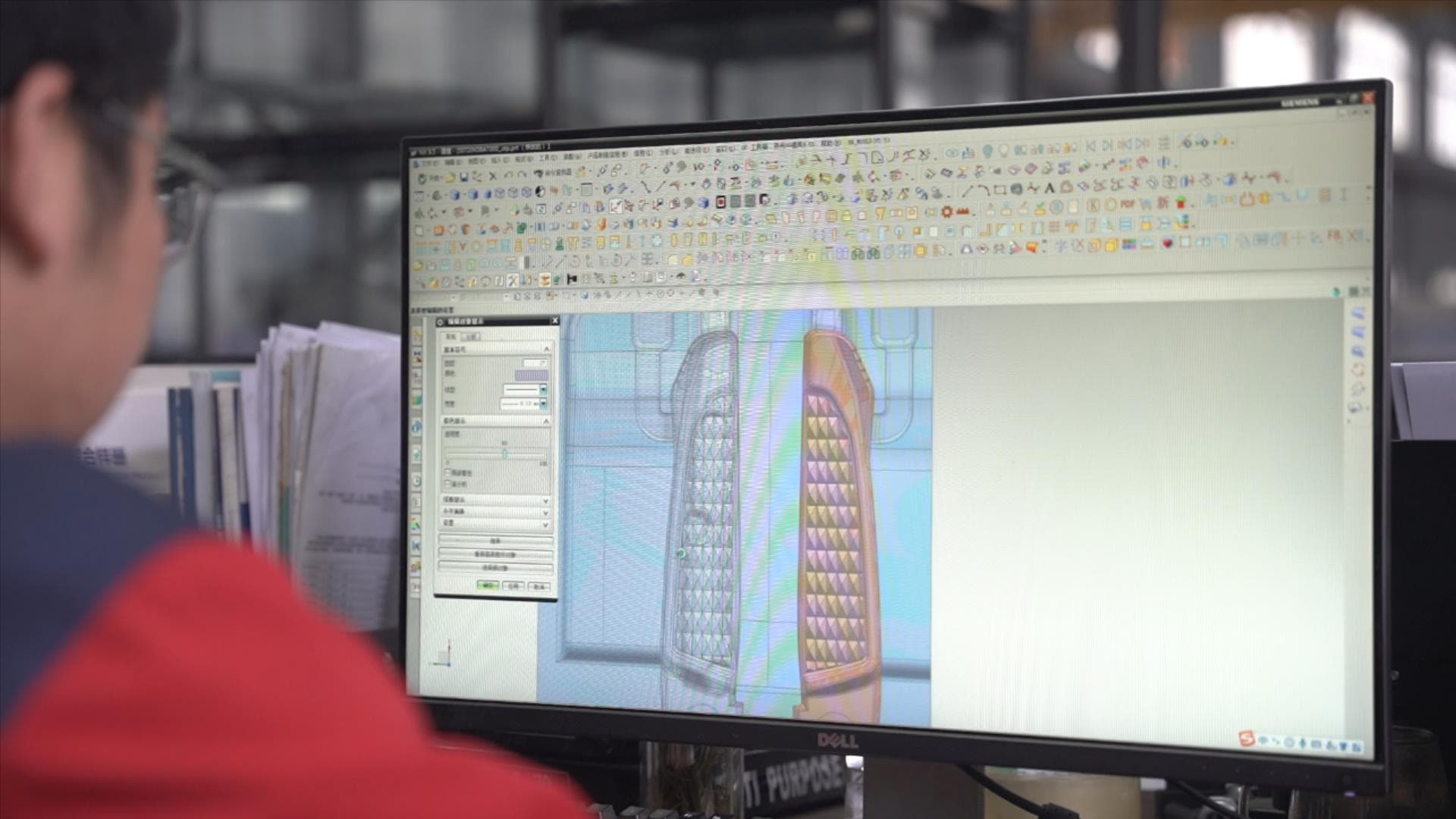

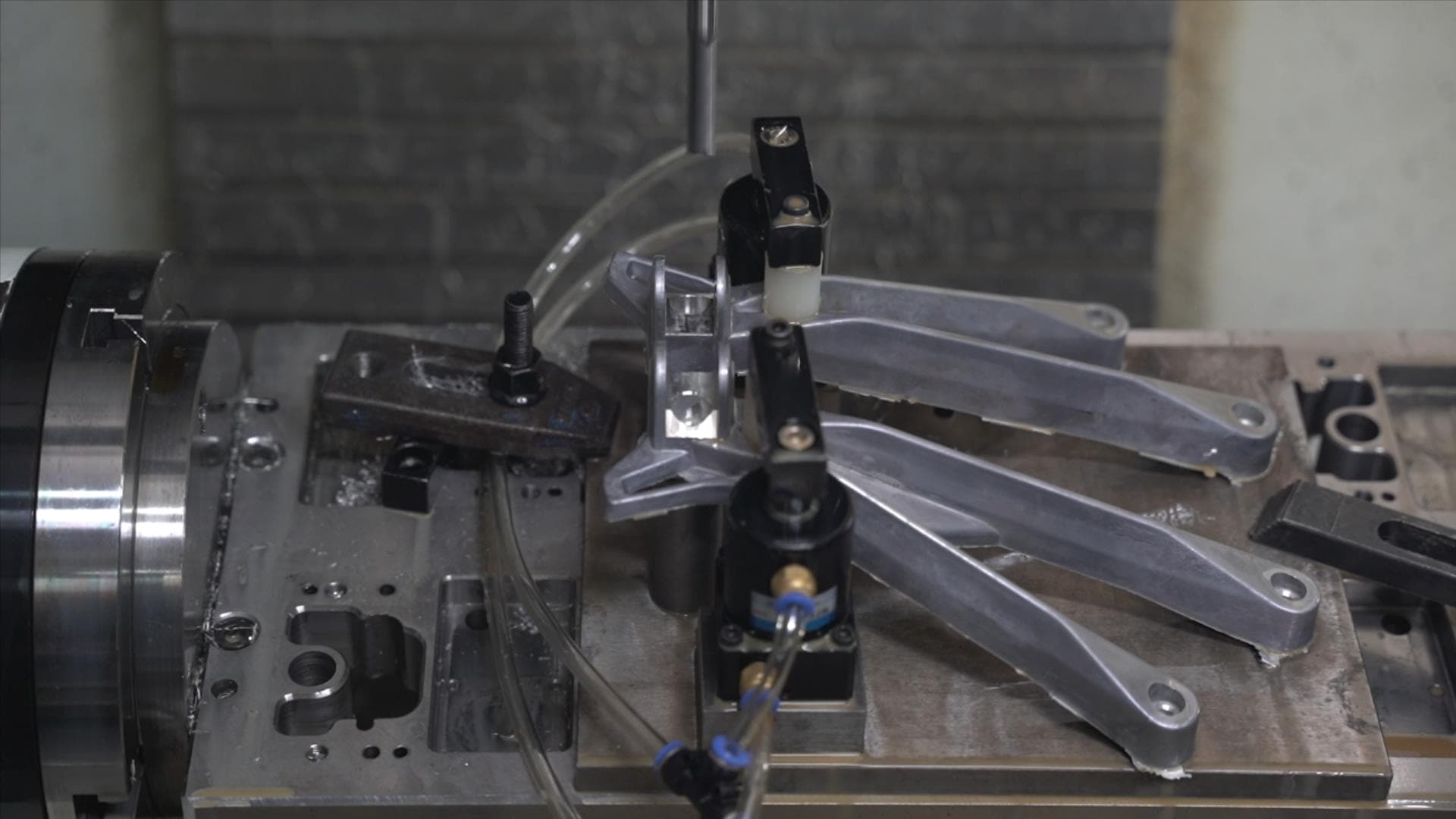

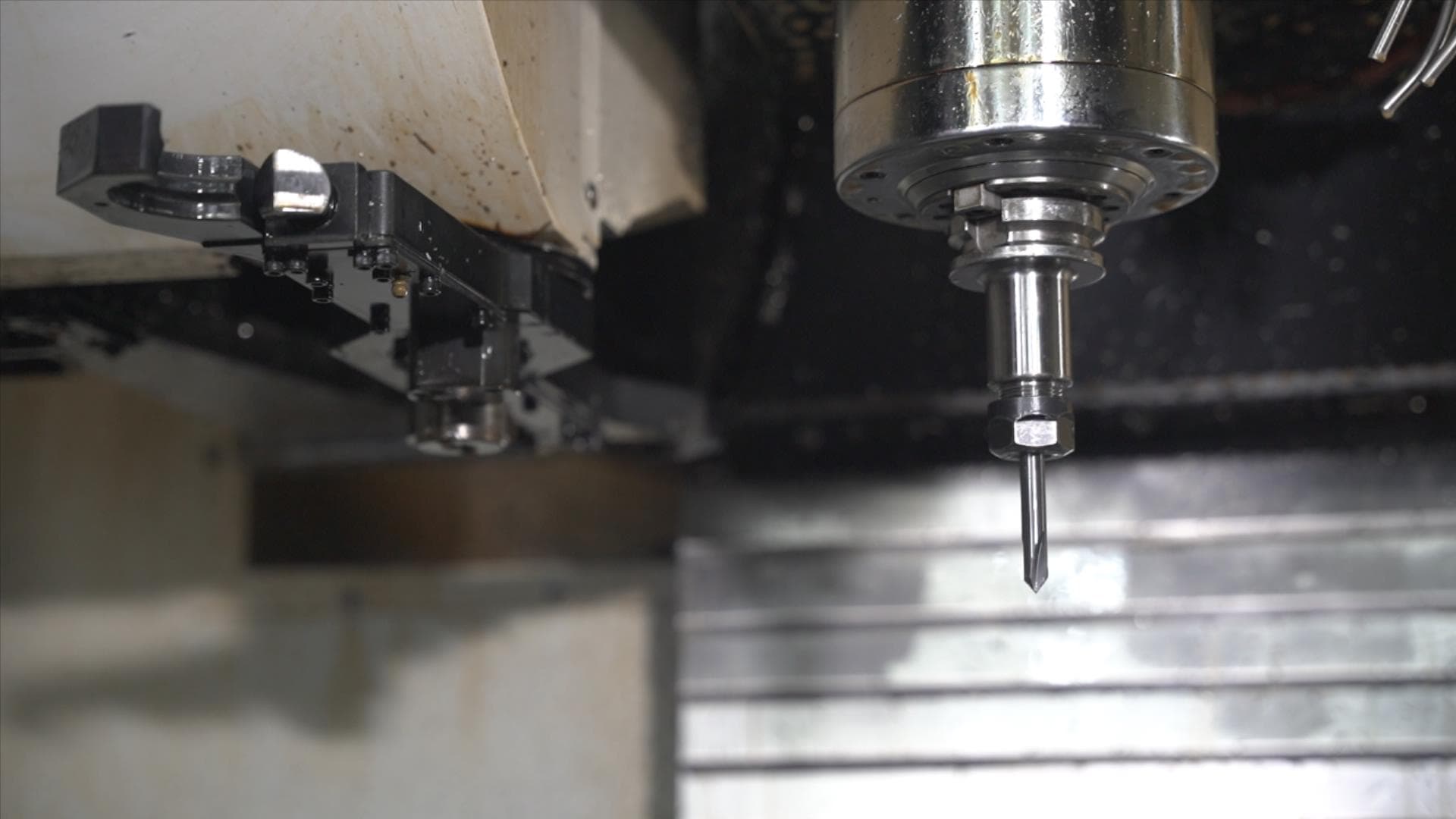

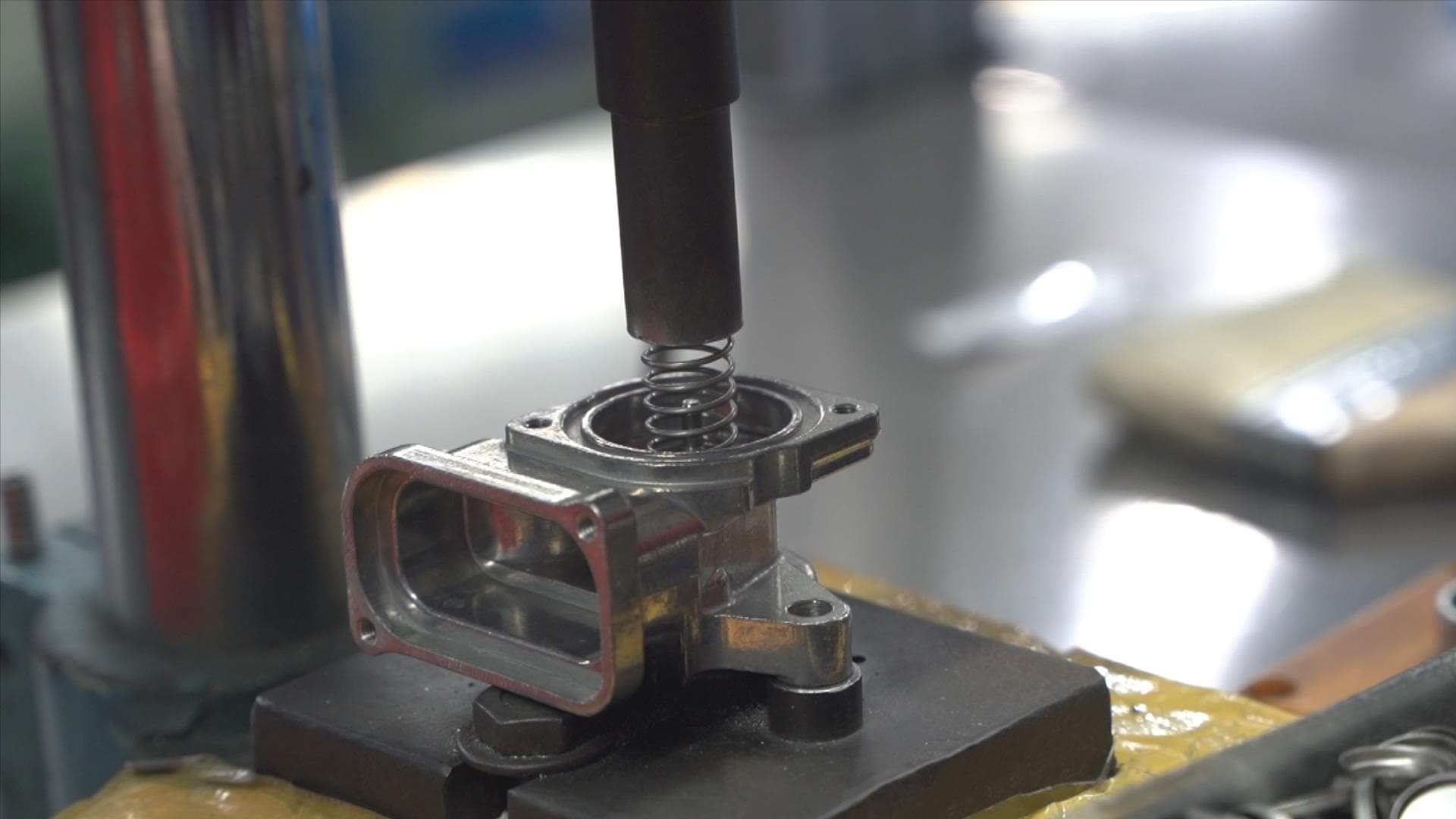

CNC machining workshop

CNC machining workshop

equipped with equipment: four-axis machining center, three-axis machining center, three-axis drilling center, two-axis precision CNC, two-axis milling CNC, two-axis CNC, two-axis instrumentation machines, single-axis CNC hobbing machine, combined bench drilling machines drilling and tapping bench drill, tapping bench drill, etc. Equipped with various professional technical programmers and introduced advanced CNC machining equipment to ensure faster and more precise completion of product processing.

Advantages of Yulong CNC machining service:

High efficiency: for multi-variety and small batch production; High precision: stable machining quality, high machining accuracy, high repetition accuracy; suitable for the development and modification of new products and modified parts.

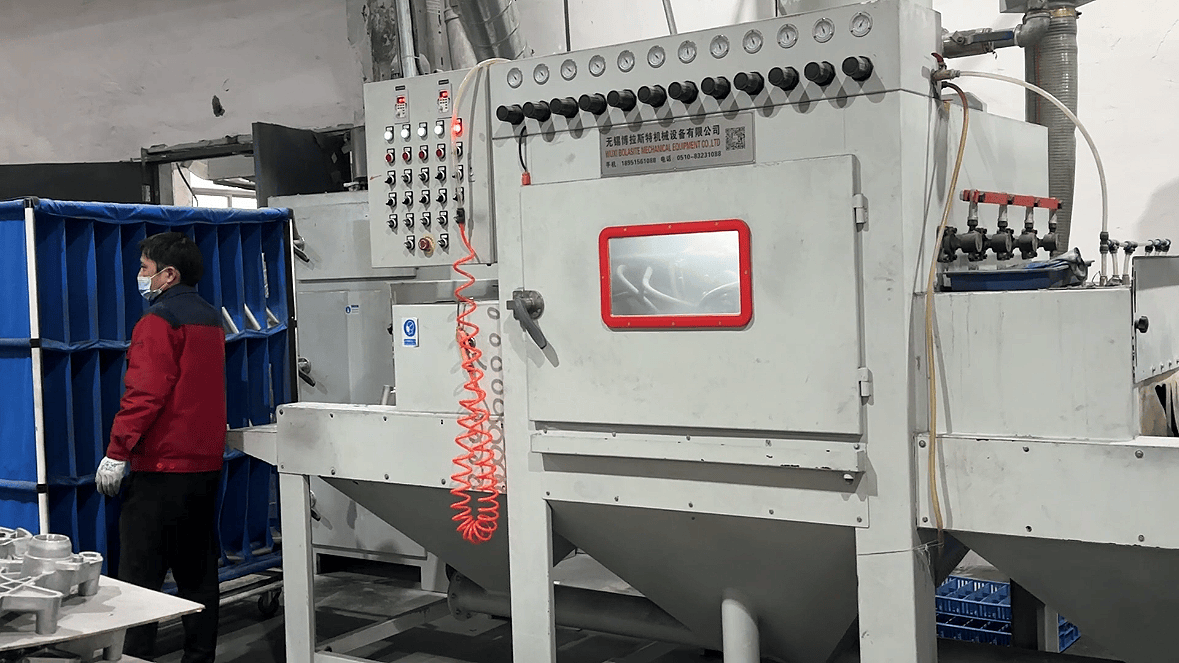

Surface treatment workshop

Surface treatment workshop

Equipped with equipment: polisher, vibration polishing machines, sandblasting machine, hanging sandblasting machine, Wet dust-removal polishing machine, dust-removal grinding machines, passivation treatment lines, UV solidifying machine, etc.

Our surface treatment includes sandblasting/polishing/grinding/passivation/vibration polishing/plastic spraying/electrophoresis/anodization, etc.

70% of the customized die-casting parts provided by Yulong to customers are appearance parts, so we have high requirements for surface treatment.

Advantages of Yulong surface treatment service:

1) It can repair good adhesion for the workpiece

2) Remove stubborn stains on the surface of the workpiece

3) Improve the performance and quality of the workpiece

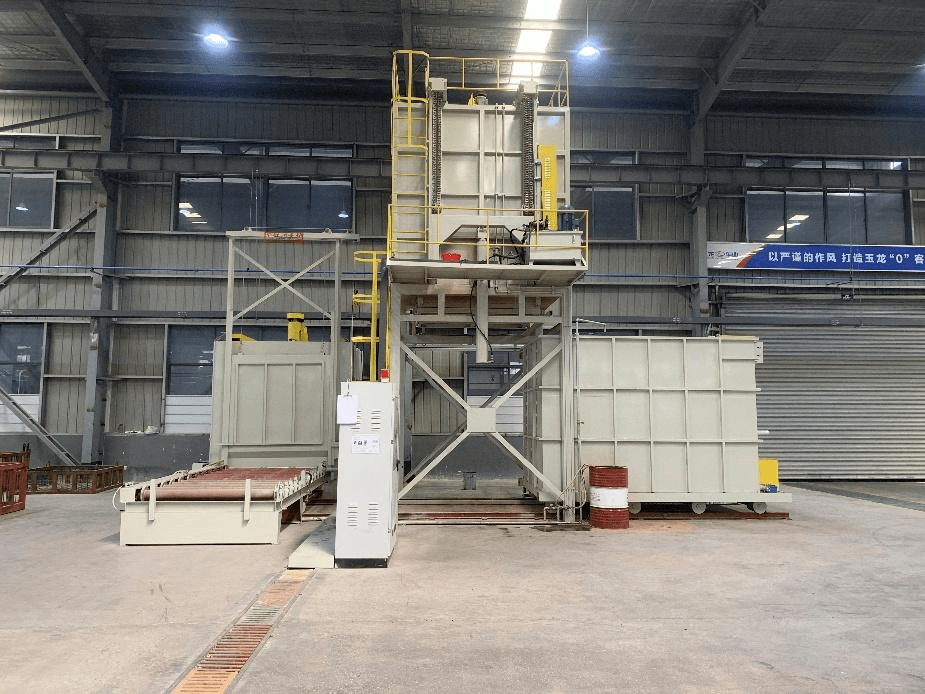

Spraying workshop

Spraying workshop

Our painting line is 760 meters long and is scientifically planned into three core areas: pre-treatment, painting, and drying, to achieve efficient and coherent operations. The pre-treatment area is about 200 meters long and includes six processes such as multi-stage spray cleaning, surface conditioning, and phosphating to fully remove impurities on the surface of the workpiece and enhance the adhesion of the coating; the spraying area occupies 60 meters and is equipped with 2 intelligent spraying robots and reciprocating machines, with an automatic paint supply system to support a variety of spraying processes; the drying area is 85 meters long and uses a segmented infrared + hot air circulation tunnel furnace to accurately control the heating, constant temperature, and cooling processes to ensure uniform curing of the coating. Each area is seamlessly connected through an intelligent conveyor chain, with a cycle time of only 5 minutes. It processes more than 40,000 workpieces per day on average, taking into account both production capacity and quality, and is widely adapted to the large-scale coating needs of industries such as automotive parts and construction machinery.

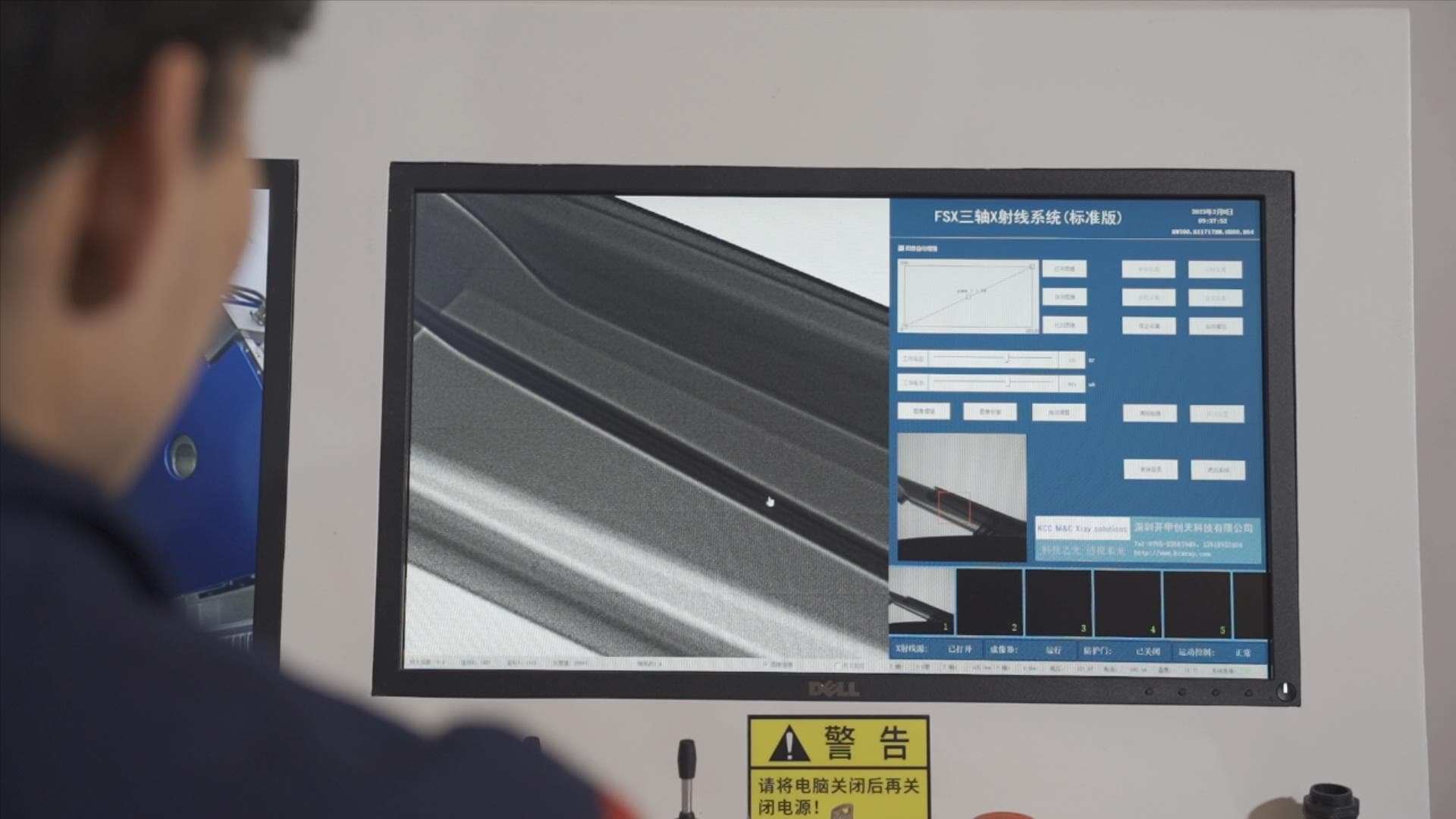

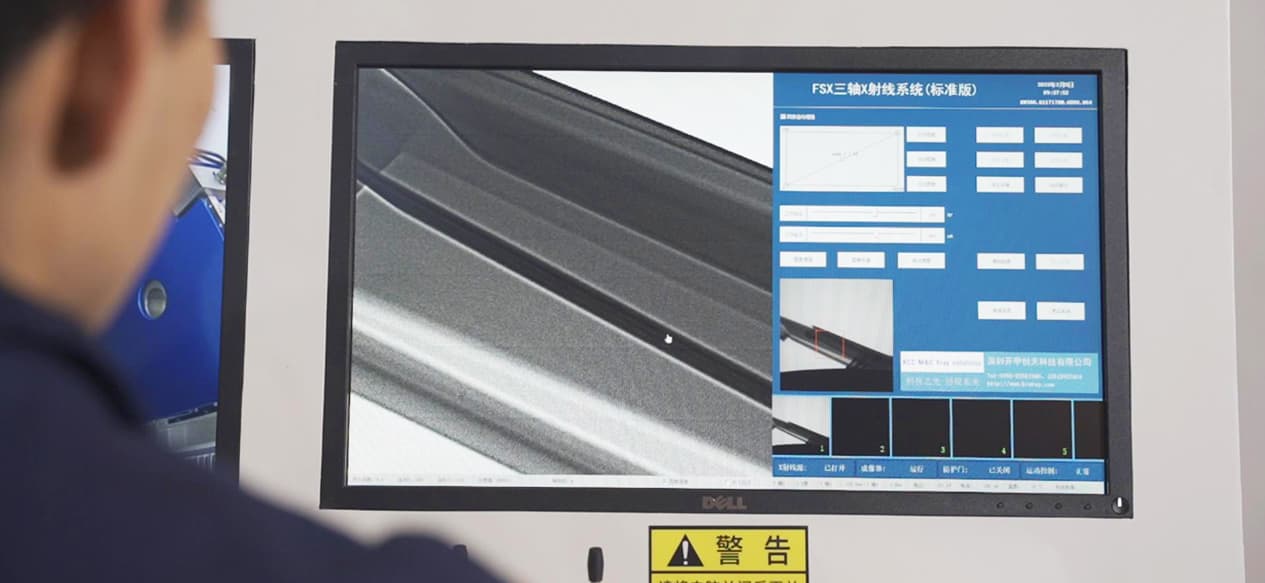

Quality Laboratory

Quality Laboratory

The company has a comprehensive laboratory with more than 30 kinds of testing equipment, including CMM, industrial flaw detectors, high&low temperature chambers, vibration testing machines, aging chambers, ozone chambers, motion durability testing machines, various hardness machines, salt spray testing chambers, etc. It can carry out tests on hardness, aging, oil resistance, ozone resistance, high and low temperature of rubber parts, durability tests of various products, and salt spray tests of surface treated parts; it carries out strict standardized testing and inspection management of raw materials and products to ensure the quality of the products before leaving the factory. After the inspection, we will provide dimension reports, material reports, detailed pictures, videos or other test reports.

Quality certification: ISO9001/ISO45001/ISO14001, IATF16949